Contact us

Leave your contact information if you are interested and we will contact you

|

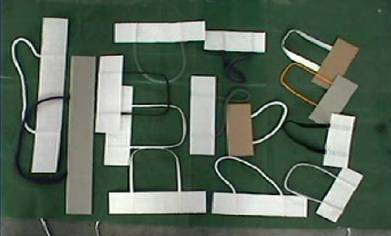

The M01ss is able to produce bulk handles: -manufacture double patch paper handles in rope in five base-sizes: MINOR, MINI, MEDIUM, MINIGIGA and GIGANT; -manufacture 14 Trimmed-sizes of double patch paper handles in rope, starting from base-sizes MINI, MEDIUM, MINIGIGA or GIGANT.

The set-up of the machine to change handle-size takes about 30 minutes. The patch may have any dimention of band-height between 40mm and 70mm. The patch paper may be from 50 to 150gsm and, coupling two of the, you can use difference ones. The handle (Fig.3), in all of their sizes, always consist of two paper patch and a rope glued on with HotMelt or with HotMelt + Vinyl glue, like a "sandwich"

Mechanical and powerful machine members enable to work up to 270 beats per minute (=540 MINI handles per minute) that decrease in proportion to the increase of patch's lenght. So the production speed will be always between said limits and from time to time it will depend also and especially on current global production conditions where the most important of them are: Competence of workers, Workability of material in use, and Condition of Use & Maintenance of the machine.

The weight of machines is about 1800 Kg, the space it takes up is about m3.2x1.2x2.0(H); its compressed air (dry and filtrate).supply is about 150 l/1' >6 bar. The machines need of 8.5kw/h of electrical energy (3x380 Vac+N+G at 50Hz). During the handle-production the machine maintains uniform quantity of HotMelt (and of Vinyl glue if present) proportioning the HotMelt pump (and the pressurized tank of Vinyl glue) with the current production speed

No° Click:15859

|